Collectors club - Club projects

Reference materials

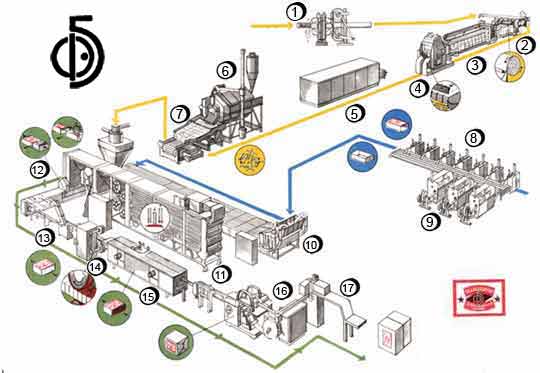

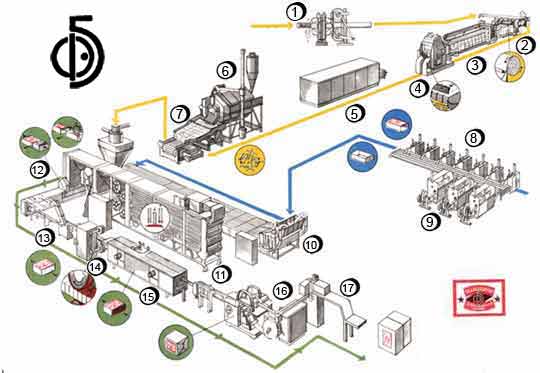

Match production technology

Automated production line

Such lines work on many match factories. including Balabanovo experimental match factory.

Vatted aspen logs are send by transporter into debarker (1). The next machine is rotary peeler that makes from them thin wooden ribbon - veneer (2).

Veneer ribbon is cut on sheets that are stacked in pile (3) and cut into splints (4) - future matches. Match splints are impregnated with special salts solutions that prevent smouldering after the fire is blown off and are dried up (5). From the dryer they go into huge drums, where they are polished (6). From the drums the polished splints are flowing into the sorting machine (7) from where airlifted into match-making automatic machine (11) where they are impregnated with paraffin, dipped into the ignition compound and dried, thus becoming matches.

In parallel with that two automated lines are preparing outer (8) and inner (9) matchboxes.

The airlift through them into boxes lining automatic machine (10), from where they are going into the match-making automatic machine to be filled with matches (12).

.

From the buffer (13) filled matchboxes are entering the striking surface "printer" (14). Then goes drying (14), wrapping in ten packs (16) and packing ten pack into transportation boxes (17).

Based on the Balabanovo experimental match factory promotional leaflet

Presented by Gennady Golyadkin

Reference materials are published only for collectors use and cannot be used in production or any other purpose.