|

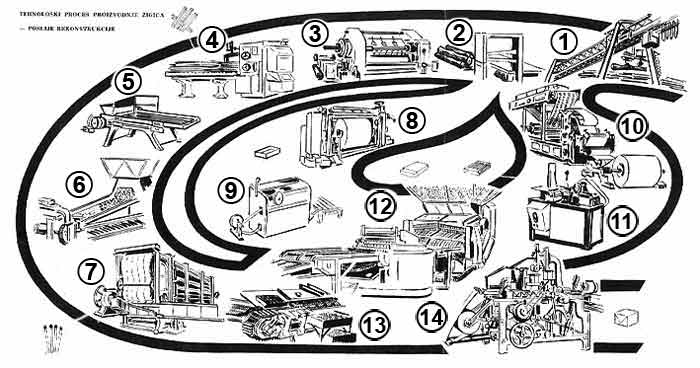

The production of match chips (items 1 to 7) remained the same as presented in the page

1. Technological process prior to the reconstruction.

The main changes and simplifications of the reconstruction concentrated onto the manufacturing of inner and outer match boxes. Replacing the wood stems the cardboard material was used to produce both types of match boxes.

8. The cardboard cutting machine produced the inner box forms. Installed were

3 machines making a total of 1.5 Millions of inner boxes daily.

9. For the daily requirement 3 machines formed and glued the inner boxes ready.

10. The cardboard cutting machine produced the outer box forms to a lattice as cut

offs for the rubbing strips to be pressed on later. Installed were 2 machines for a

daily production of 1.5 Millions of outer boxes.

11. Under the daily production condition 2 automatons formed and glued the outer

boxes ready that included pressing on the rubbing strips to the finish.

12. The ready inner and outer boxes were transported by air-slides to the next of

one of the two (2) machines where the inner boxes were filled with the right

type and number of match-chips and the outer boxes pushed over afterwards.

13. Subsequently the ready match boxes were moved on air-slides to the next

machinery where etiquettes were glued on and sorted out for the next move.

14.In a large machine sorted match-boxes were stapled first to form small packages

containing 10 pieces of boxes. In following step these packages were wrapped

into larger packets containing a total of 2.000 match-boxes ready for the export.

|

Pages:

Pages:

0

0

1

1

2

2

3

3

4

4

5

5

Pages:

Pages:

0

0

1

1

2

2

3

3

4

4

5

5